Transforming Equipment & Tool Management: An RFID Guide for Manufacturing, Construction, and MRO Businesses

Jan 25, 2026

In the bustling workshops of manufacturing plants, across sprawling construction sites, and within the service vehicles of maintenance teams, managing equipment and tools has long been a universal challenge. Where are the assets? Who is using them? What is their status? When is maintenance or calibration due? Traditional methods like paper logs and manual audits are not only inefficient and error-prone but also lead to low asset utilization, unplanned downtime, and significant losses from misplaced tools.Today, Internet of Things (IoT) solutions centered on Radio Frequency Identification (RFID) technology are driving a profound transformation in asset management. It is far more than just an “electronic tag”; it is a systematic solution for achieving full lifecycle, visible, and intelligent management of equipment and tools.

Core Industry Pain Points: Why Is Management So Difficult?

Before diving into the RFID solution, let's clarify the common challenges across these sectors:Poor Asset Visibility: High-value machinery, specialized tools, or critical spare parts are difficult to locate in real-time across vast facilities or dispersed job sites, consuming productive hours in "search time."Low Utilization Rates: Equipment and tools are often forgotten in corners or hoarded by individuals, preventing effective sharing and scheduling, leading to unnecessary duplicate purchases.Reactive Maintenance & Missed Calibrations: Preventive maintenance and mandatory calibration schedules reliant on human memory or paper records are easily missed, risking equipment failure, safety incidents, and quality non-compliance.Time-Consuming Physical Audits: Traditional inventory counts require operations to halt, are labor-intensive, and yield inaccurate data.Significant Loss & Shrinkage: Unintentional "walk-aways" or poor oversight of tools result in substantial financial loss.

The RFID Solution: How to Build a "Smart Asset Network"

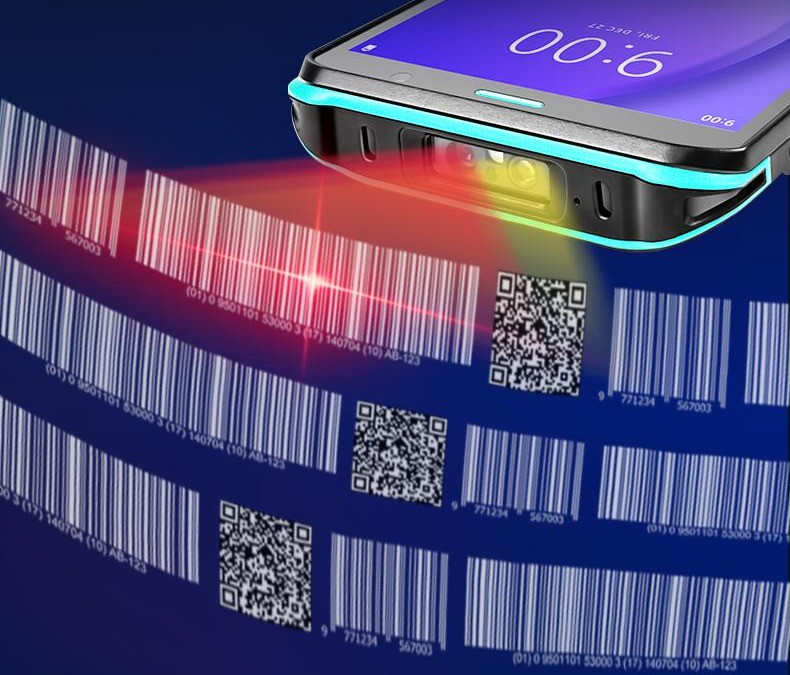

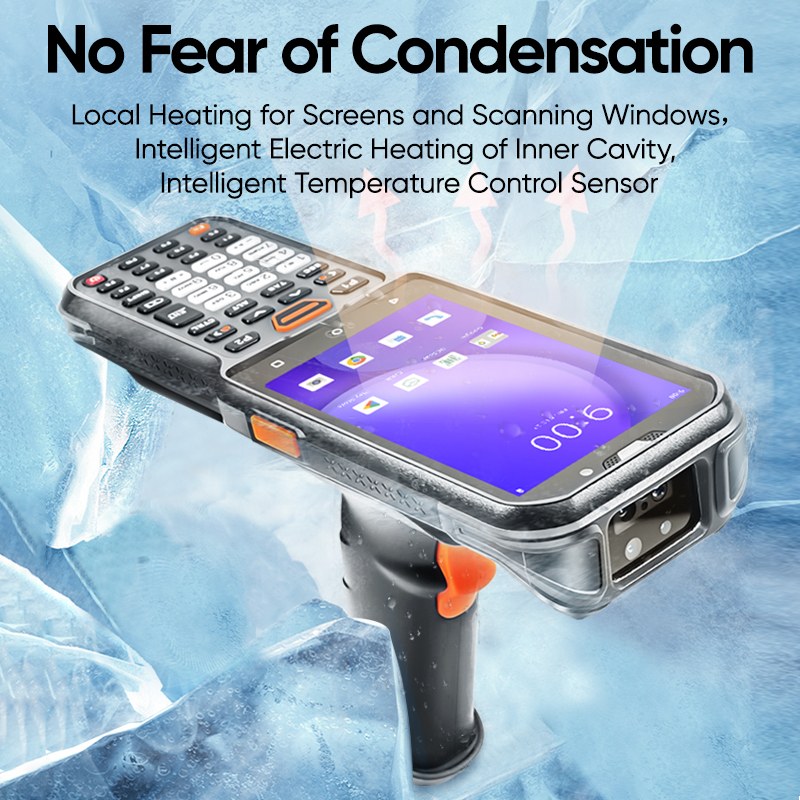

An RFID system creates an intelligent management network by giving each item a unique "digital ID" (RFID tag) and integrating it with fixed or handheld readers, network infrastructure, and software platforms.1. Core Hardware Components:Metal-Mount RFID Tags: Engineered for metal assets, these tags withstand high temperatures, resist oils and chemicals, and endure impacts. They can be embedded or directly attached, thriving in harsh industrial environments.Fixed Readers & Antennas: Installed at tool crib entrances, key facility choke points, or in service vehicles, they enable automated check-in/check-out and zone-level tracking.Rugged Handheld RFID Terminals: Used for mobile inventory audits, on-site location checks, and work order associations. Staff can rapidly read multiple tags from a distance without line-of-sight.2. Enabling Smart Management Scenarios:Smart Tool Crib / Warehouse Management:Automated Issuance & Returns: Upon employee badge scan, the system automatically records tools removed (via entry/exit readers) and verifies returns, enforcing accountability.Rapid Inventory Audits: Full facility audits that took days can now be completed in hours with near 100% accuracy using a handheld terminal.Automated Alerts: The system triggers alerts for tools not returned or when stock falls below minimum levels.

Production & Workflow Optimization:Work Order Kitting: Required tool lists are digitally linked to production or maintenance work orders. The system validates picks at issuance to prevent errors.Work-in-Progress Tracking: In manufacturing, RFID tags on jigs, fixtures, and molds enable real-time tracking of their location and status.Site-Level Location: On construction sites, readers deployed in zones provide granular location data for large equipment or high-value tools.Maintenance & Compliance Assurance:Automated Maintenance Triggers: The system generates preventive maintenance work orders based on actual usage hours or cycles.Calibration Cycle Management: For measuring instruments, the system alerts before calibration expires and can restrict checkout, ensuring only compliant tools are used.Complete History & Traceability: A full digital history of usage, maintenance, and repair is maintained for each asset, creating a digital twin record.

Industry-Specific Value Propositions

Manufacturing: Increases Overall Equipment Effectiveness (OEE), ensures availability of critical line-side tooling, and reduces production stoppages caused by missing fixtures.Construction: Manages large equipment (e.g., crane modules, generators) and vast quantities of power tools scattered across multiple projects, reducing loss rates and optimizing inter-project scheduling.MRO & Facility Management: Ensures technicians' service vehicles are stocked with the correct, compliant tools, accurately tracks tool usage costs, and enhances service response speed and professionalism.Measuring ROI: The Tangible Benefits

The return on investment from an RFID deployment is multi-faceted:Direct Cost Savings: Reduce tool loss by 50-80%, increase asset utilization by 20-35%, and cut inventory labor costs by over 90%.Operational Efficiency Gains: Eliminate up to 30% of time spent searching for items, reduce equipment downtime, and accelerate job completion.Risk & Compliance Control: Eliminate the use of out-of-calibration tools, achieve 100% scheduled maintenance compliance, and significantly enhance safety and quality standards.Data-Driven Decision Making: Make smarter procurement, retirement, and resource allocation decisions based on accurate, real-time asset data.

Implementation Roadmap: Your Path to Smarter Management

A successful RFID project starts with clear planning:Start with a Pilot: Choose a high-pain-point area like a main tool crib or a specific project to validate the technology and quantify benefits.Tag Selection is Critical: Choose the right RFID tag based on asset material, size, and environmental exposure (temperature, chemicals, impact).Process Re-engineering: Technology is an enabler. Optimize your management processes and policies to leverage its full potential.System Integration: Ensure RFID asset data flows into your existing ERP, CMMS (Computerized Maintenance Management System), or project management software to break down information silos.ConclusionFor manufacturing, construction, and MRO businesses, equipment and tools are not just cost centers—they are core productivity drivers that create value, ensure safety, and guarantee quality. RFID technology transforms these passive assets into connected, communicative data points, building a transparent, efficient, and reliable intelligent asset management ecosystem. This is no longer a choice about "tags," but a strategic decision to enhance core competitiveness and step into the era of Industry 4.0 and smart operations. The time to audit your assets and empower them with intelligence is now.

We are FYJ, a specialized provider of RFID hardware and software solutions with 12 years of professional expertise. We are committed to delivering reliable and innovative asset management technologies for global manufacturing, construction, and maintenance businesses. If your company is facing challenges in equipment and tool management, please contact us for a free customized solution assessment and product trial opportunity. Let our expertise help you achieve a leap in operational efficiency.

--------------------

Read More